In modern manufacturing, grinding isn’t just a mechanical step—it’s a cornerstone of product excellence. For producers working with complex spice mixtures or pharmaceutical powders, choosing the right equipment means achieving the perfect balance between speed, consistency, and purity. At MillNest, we’ve designed two advanced solutions that meet these very different demands: the MAHM and the MACM.

Why Your Grinding System Is More Than Just a Machine

Every production facility has its own rhythm. Whether you’re pulverizing bulk turmeric or formulating delicate APIs, particle size control, heat management, and throughput all come into play. While a hammer mill for spice grinding can power through fibrous material, classifying mills shine when it comes to fine-tuning micron-level output for pharma-grade batches.

MAHM: Designed for Aggressive Spice Throughput

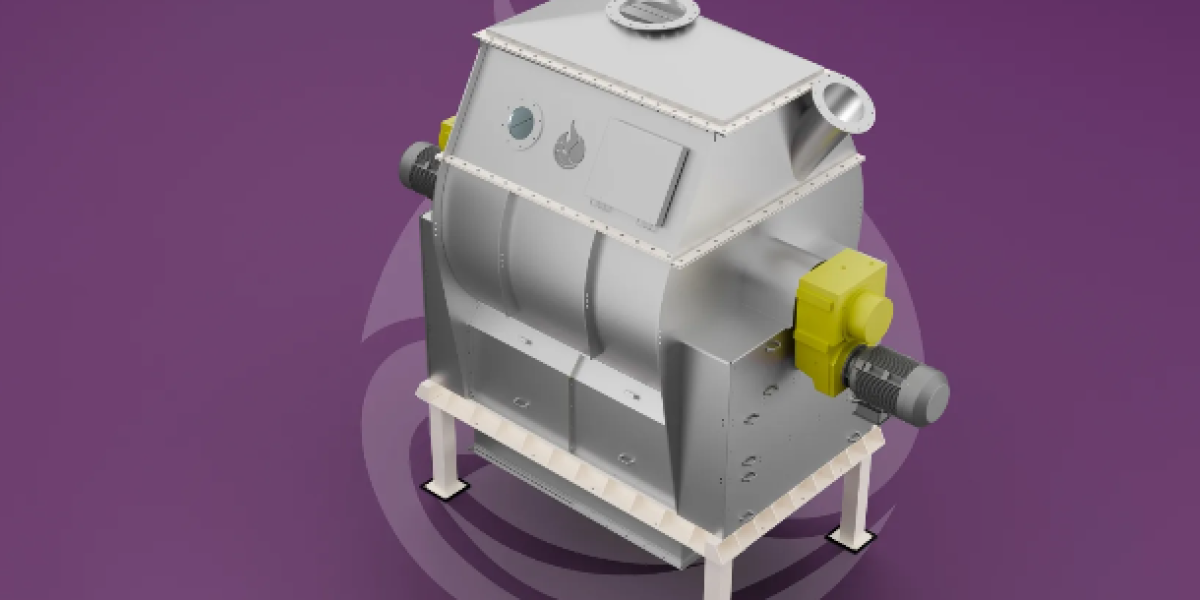

Built with spice processors in mind, the MillNest Advanced Hammer Mill (MAHM) delivers high-speed impact grinding that’s ideal for breaking down tough ingredients like dried chilies, coriander seeds, and cardamom pods.

Its robust design ensures minimal downtime, and optional add-ons—such as waste heat recovery solutions—help conserve energy while keeping production lines efficient. For high-volume spice brands, MAHM offers reliability with easy maintenance and integration capabilities.

MACM: Precision-Engineered for Cleanroom-Grade Powders

For manufacturers working with nutraceuticals or pharmaceutical powders, precision and hygiene take precedence. The MillNest Air Classifying Mill (MACM) features an enclosed design and integrated particle size classification, ensuring every output meets strict purity and uniformity standards.

This setup minimizes thermal degradation and supports cooling options, making it ideal for sensitive compounds and bioactives. It’s a pharmaceutical hammer mill that performs with scientific accuracy.

MAHM vs. MACM: Which One Works for You?

| Parameter | MAHM – Hammer Mill | MACM – Classifying Mill |

| Application Focus | Spices (turmeric, pepper, herbs) | Pharma-grade powders, botanicals |

| Grinding Principle | High-speed hammer impact | Air classification + grinding |

| Particle Size Consistency | Moderate to high | Ultra-precise (narrow PSD) |

| Heat Control | Good (with WHR integration) | Excellent (cooling-ready) |

| Cleanroom Compatibility | General food-grade | High-purity pharma standard |

| Maintenance | Tool-free, modular | Cleanroom-compliant |

| Energy Optimization | Available with WHR systems | Low thermal footprint |

Finding the Right Fit for Your Workflow

Go with MAHM if your primary goal is processing bulk spices fast and efficiently. It’s tailor-made for exporters, food manufacturers, and seasoning producers who value throughput and ruggedness.

On the other hand, if your production requires fine control over particle size, cleanroom compliance, and heat-sensitive processing, the MACM is your best choice.

Looking to complement your setup? Our MillNest Paddle Blender offers post-grind uniform mixing—especially useful for customized spice blends and powdered supplements.

More Than Machines—We Build Processing Solutions

At MillNest, we’re committed to designing systems that evolve with your needs. From dust control to automated packaging lines, our modular systems scale with you. Whether you’re optimizing your spice plant or expanding into pharmaceutical-grade operations, we’re here to guide your journey from idea to execution.