In today’s competitive industrial landscape, a single miscalculation in component design can result in costly production delays or even equipment failure. Whether you’re developing parts for aerospace, automotive, or consumer electronics, the need for reliable, high-precision manufacturing has never been greater. This is where CNC machining comes into play. To ensure long-term performance and quality, one must understand what is cnc machining and how it has transformed modern fabrication processes across industries.

Why CNC Machining Is Critical to Product Success

CNC (Computer Numerical Control) machining plays an indispensable role in high-accuracy manufacturing environments. As tolerances become tighter and materials more advanced, manual methods are simply not feasible for producing scalable, repeatable, and high-performance components. This applies especially in sectors like aerospace, medical devices, defense, automotive, and semiconductor tooling—where a few microns can determine operational success.

Moreover, CNC machining directly impacts part consistency, surface finish, and mechanical integrity. Whether working with stainless steel, aluminum, or engineering plastics, using a digital workflow eliminates human error and reduces rework rates. Terms like geometric dimensioning and tolerancing (GD&T), toolpath optimization, and 5-axis machining are now central to any engineering conversation. Understanding how this technology operates is key to designing parts that are both manufacturable and cost-efficient.

Technical Foundations of CNC Machining

What Is CNC Machining?

CNC machining refers to a subtractive manufacturing process where computer-controlled machines remove material from a solid block (called a workpiece) using cutting tools. The instructions are generated via CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, ensuring every movement is preprogrammed to meet specific dimensions and tolerances. Unlike manual machining, CNC allows continuous, precise, and automated production—even for highly complex geometries.

Common CNC operations include:

-

Turning: Removing material as the workpiece rotates.

-

Milling: Rotating cutting tools remove material while the workpiece stays stationary.

-

Drilling, boring, and tapping: Used for creating accurate holes and threads.

-

EDM (Electrical Discharge Machining): Ideal for hard materials and intricate shapes.

CNC is scalable for prototyping, small-batch runs, and full-scale production across industries.

Why Material Selection Matters

Material compatibility is vital in CNC machining. Engineers must balance strength, machinability, thermal properties, and cost. For example:

-

Aluminum alloys are lightweight and ideal for aerospace parts.

-

Stainless steel offers excellent corrosion resistance for medical and food-grade components.

-

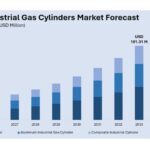

Nickel alloys are used for extreme environments like gas turbines.

-

Engineering plastics like Delrin or PEEK are common in electronics and medical device housings.

Each material behaves differently during cutting—impacting feed rate, tool wear, and surface finish. An expert CNC shop like MYT Machining understands how to optimize setup based on the unique properties of each material.

Tolerances, Surface Finish, and Precision

Tolerances refer to the allowable deviation from a nominal dimension. In high-spec industries, tolerances can be as tight as ±0.005 mm. Surface finish, meanwhile, affects friction, fit, and aesthetics. CNC machining offers finishes ranging from rough cuts to mirror-like polish, depending on tooling and post-processing.

Geometric dimensioning and tolerancing (GD&T) is often used to communicate complex part requirements—ensuring all features are machined relative to one another, not just in isolation. Partnering with a CNC vendor familiar with GD&T is critical to avoiding interpretation errors and ensuring functionality.

Real-World Application Examples

-

Aerospace: CNC machining is used for high-stress engine brackets and lightweight structural components that must meet FAA standards.

-

Medical Devices: From surgical instruments to orthopedic implants, precision and biocompatibility are non-negotiable.

-

Automotive: Transmission housings, suspension parts, and engine components benefit from CNC’s repeatability.

-

Electronics: CNC machining produces heat sinks, connectors, and enclosures with exacting standards for fit and performance.

These sectors demand a partner who not only understands design requirements but can also deliver consistent results with zero compromise.

How to Choose a CNC Machining Partner That Delivers Results

Choosing the right CNC machining service isn’t just about cutting metal—it’s about collaboration, communication, and quality control. Here are key factors that engineers and procurement managers should prioritize:

Key Selection Criteria:

-

Certifications: Look for ISO 9001 or AS9100 for aerospace work. These ensure quality management systems are in place.

-

Material Expertise: Can the shop handle exotic alloys, tight-tolerance plastics, or both?

-

Advanced Capabilities: 5-axis machining, in-process inspection, and automation are essential for complex, multi-part assemblies.

-

Lead Times and Scalability: The ability to move from prototype to production quickly is critical for time-sensitive projects.

Why MYT Machining Is the Trusted Choice

At MYT Machining, we blend precision with partnership. Our facilities are equipped with state-of-the-art CNC turning, milling, and multi-axis systems that handle everything from aluminum to Inconel. We serve startups, OEMs, and product designers who require accuracy, consistency, and a responsive support team.

Clients rely on MYT not only for technical skill but also for our ability to help refine part designs for manufacturability, reducing both cost and production time. Our deep library of expert resources, combined with extensive in-house capabilities, allows us to deliver high-quality parts at competitive turnaround times—whether for aerospace brackets or microfluidic device housings.

Final Thoughts: Precision Drives Innovation

In a world where product timelines are shrinking and quality demands are rising, CNC machining serves as the foundation of modern manufacturing. It enables engineers to bring designs to life with precision and repeatability—whether you’re building a prototype or scaling production.

Understanding how CNC works is the first step. Choosing a machining partner who can translate that understanding into quality parts is the next. Companies like MYT Machining offer more than machining—they offer peace of mind, technical clarity, and consistent results. For a deeper look into our services or to request a quote, visit our website and explore how we support engineers at every stage of the product lifecycle.