Polycarbonate (PC) hollow sheets have become increasingly popular across various industries due to their unique combination of strength, lightweight properties, and versatility. These sheets, often used in construction, signage, and agricultural applications, are a modern solution for projects requiring durability, insulation, and resistance to external factors like UV rays and harsh weather conditions. Known for their lightweight structure and impact resistance, PC hollow sheets are made from polycarbonate, a high-performance thermoplastic polymer. In countries like India, the demand for Pulkit Plastic Products has been growing steadily, especially in the construction and agricultural sectors, where these materials are frequently used in roofing, skylights, and greenhouses.

Understanding the Composition and Structure of PC Hollow Sheets

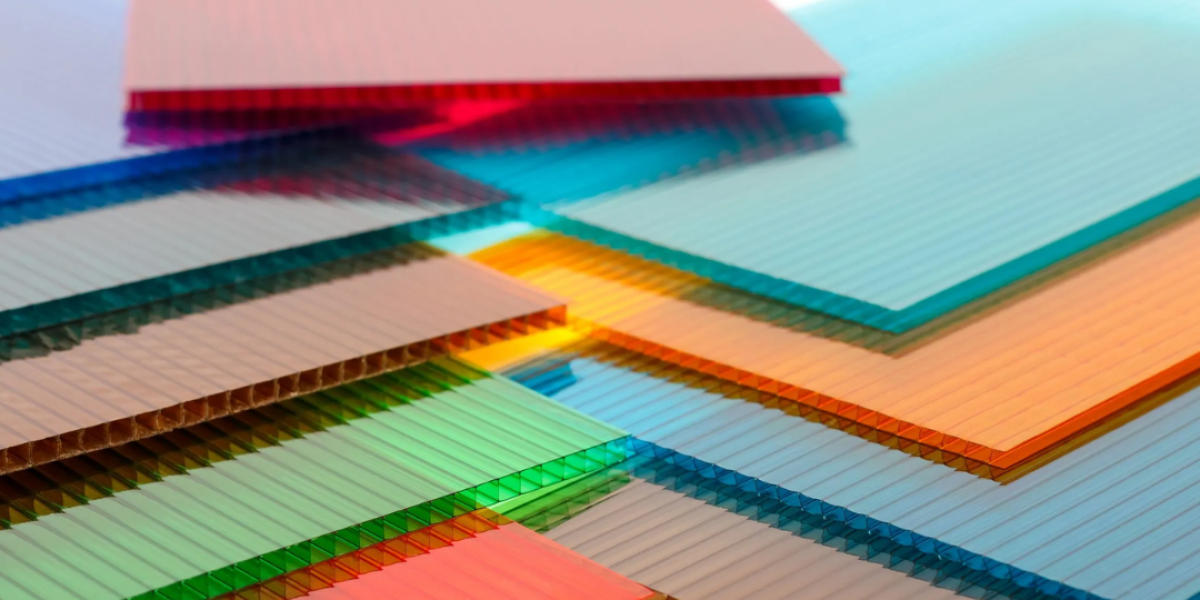

PC hollow sheets are created by extruding polycarbonate into multi-wall sheets with hollow spaces between the layers. This multi-layer structure contributes to the sheets’ strength and insulating properties. These sheets typically come in two or three layers, though more complex configurations exist, offering varying levels of thermal insulation and soundproofing. The hollow chambers in the sheets are designed to trap air, which helps maintain temperature control in buildings and greenhouses, while also providing significant structural integrity despite their lightweight nature. In India, polycarbonate sheets are often used for commercial and residential applications due to their ability to combine functionality with aesthetic appeal. These sheets also offer high resistance to impact, which makes them ideal for areas prone to harsh weather conditions, such as hailstorms.

Key Features and Benefits of PC Hollow Sheets

The widespread use of Polycarbonate sheets is due to the numerous benefits they offer. One of the most notable advantages is their lightweight yet durable nature, which makes them easy to handle and install without compromising on strength. The multi-layered design not only enhances their structural strength but also provides exceptional insulation, which is ideal for reducing energy costs in buildings. This insulation helps maintain a comfortable temperature indoors, whether it’s protecting against the heat of the sun or preserving warmth during cooler months.

Another significant benefit of PC hollow sheets is their UV resistance. Polycarbonate inherently blocks harmful UV rays, and many manufacturers apply a special UV coating to the surface of these sheets to extend their longevity. This feature makes them a perfect choice for applications like skylights, roofing, and greenhouses, where exposure to the sun is constant. Additionally, polycarbonate sheets are known for their impact resistance, providing protection from external forces, such as hail or falling debris, making them a safer choice than glass or acrylic alternatives.

Applications of PC Hollow Sheets in India

In India, PC hollow sheets are being widely adopted in construction and agriculture due to their remarkable properties. The construction industry has increasingly turned to polycarbonate roofing solutions, especially in cities and areas with high temperatures. Polycarbonate sheets are perfect for roofing, skylights, and wall cladding due to their ability to provide natural daylighting without the heat transfer that typically accompanies traditional glass. Their ability to diffuse light evenly while blocking harmful UV rays makes them an excellent choice for energy-efficient buildings.

In the agricultural sector, polycarbonate hollow sheets are often used in the construction of greenhouses. These sheets help maintain optimal growing conditions by regulating temperature and humidity levels inside the greenhouse. The insulation properties of PC sheets reduce the need for artificial heating or cooling, helping farmers save on energy costs. Furthermore, these sheets’ impact resistance ensures that the greenhouse can withstand extreme weather conditions, protecting delicate crops from damage. Due to the increasing need for sustainable farming practices, PC hollow sheets have emerged as a crucial material in modern agricultural infrastructure.

Durability and Environmental Considerations of PC Hollow Sheets

One of the most important qualities of PC hollow sheets is their durability. Polycarbonate sheets are known for their high impact resistance, which means they are much more durable than traditional materials like glass or acrylic. This makes them an excellent choice for roofing applications where weather conditions can be unpredictable and harsh. In India, where the climate varies significantly across regions, polycarbonate sheets provide a long-lasting solution that withstands the effects of UV radiation, rain, wind, and other environmental factors.

Another key environmental consideration is that PC hollow sheets are fully recyclable. The ability to reuse polycarbonate sheets helps reduce waste in the construction and agricultural sectors, where large volumes of material are used. Additionally, the energy-efficient properties of polycarbonate sheets—in terms of insulation and heat regulation—contribute to overall sustainability by reducing the need for additional heating or cooling in buildings and greenhouses, thereby lowering energy consumption. As a result, the environmental impact of using these materials is significantly lower than that of other less efficient options, making PC hollow sheets a smart choice for eco-conscious builders and agriculturalists.

Challenges in PC Hollow Sheet Production and Usage

Despite their many advantages, Polycarbonate sheet price are not without their challenges. One of the primary hurdles in the production and usage of polycarbonate sheets is the cost. Polycarbonate is a higher-cost material compared to other alternatives, such as PVC or acrylic, which may deter some builders and consumers from opting for it. Additionally, while polycarbonate sheets are known for their impact resistance, they can still be prone to scratching, particularly if not treated with protective coatings. Care must be taken during installation and maintenance to preserve the aesthetic qualities and longevity of the material.

Another challenge is related to the complexity of installation. Because of their multi-layered structure, PC hollow sheets require specialized installation techniques to ensure proper sealing and minimize air gaps that could affect insulation. Inexperienced installers may find it challenging to work with polycarbonate sheets, leading to installation errors that can compromise the effectiveness of the material. Proper guidance from polycarbonate sheet manufacturers is essential to ensure the sheets are installed correctly and perform to their full potential.

The Future of PC Hollow Sheets in India and Beyond

The demand for PC hollow sheets is expected to continue growing, especially as industries and consumers become more focused on sustainability and energy efficiency. In India, where infrastructure development and agricultural modernization are ongoing, polycarbonate sheets will likely play an increasingly important role in shaping the future of construction and farming. The ability of PC hollow sheets to provide both thermal insulation and UV protection while being lightweight and durable positions them as a key material for the next generation of eco-friendly buildings and sustainable agricultural practices.

As technology continues to advance, we may also see innovations in polycarbonate sheet manufacturing, including improvements in durability, cost-efficiency, and ease of installation. Research into polycarbonate sheets will likely lead to the development of new variants that are even more energy-efficient, eco-friendly, and affordable, making these materials more accessible to a wider range of consumers and industries. The growing trend of sustainability and energy efficiency ensures that PC hollow sheets will remain a staple material in construction and agriculture for years to come.

Conclusion: The Value of PC Hollow Sheets in Modern Applications

In conclusion, PC Sheet in India offer a wide range of benefits that make them an essential material in the construction, agricultural, and manufacturing industries. Their combination of strength, lightweight design, thermal insulation, UV protection, and impact resistance makes them an ideal choice for a variety of applications, from roofing to greenhouses. As polycarbonate sheet manufacturing advances, the material will continue to evolve, providing even more sustainable and cost-effective solutions to meet the demands of the modern world. The growing popularity of PC hollow sheets in India is a testament to their versatility and the value they bring to industries seeking efficient, durable, and eco-friendly materials.

Frequently Asked Questions (FAQs)

1. What are the main advantages of PC hollow sheets?

PC hollow sheets offer several advantages, including lightweight design, high impact resistance, excellent thermal insulation, UV protection, and durability. They are also energy-efficient, which makes them ideal for use in construction and agriculture.

2. How do PC hollow sheets contribute to energy efficiency in buildings?

The multi-layered structure of PC hollow sheets traps air between the layers, providing excellent insulation. This reduces the need for artificial heating or cooling, helping to maintain a comfortable temperature indoors and lowering energy consumption.

3. Are PC hollow sheets recyclable?

Yes, PC hollow sheets are fully recyclable. Polycarbonate is a recyclable material, and used sheets can be processed and reused in new products, contributing to a more sustainable construction and agricultural infrastructure.

4. What is the cost of PC hollow sheets compared to other materials?

While PC hollow sheets are more expensive than alternatives like PVC or acrylic, their durability, insulation properties, and UV resistance make them a long-term investment that can provide savings on energy costs and maintenance over time.