Introduction

As industries increasingly focus on eco-friendly manufacturing, recycling foam and sponge materials has become a key priority. A sponge recycling machine provides an innovative solution to repurpose discarded foam waste, reducing environmental impact while optimizing material usage. These machines help businesses streamline production, cut costs, and contribute to a more sustainable future.

What is a Sponge Recycling Machine?

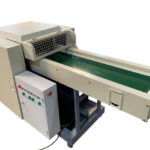

A sponge recycling machine is designed to process used sponge and foam waste, breaking it down and reforming it into reusable materials. Instead of discarding foam scraps, manufacturers can reintegrate them into new production cycles, minimizing waste and maximizing resource efficiency.

How Does a Sponge Recycling Machine Work?

- Material Collection – Used sponge materials are gathered and prepared for recycling.

- Shredding & Grinding – The machine reduces the sponge into smaller, manageable pieces.

- Rebonding Process – The shredded material is bonded using adhesives or heat.

- Molding & Pressing – The recycled sponge is compressed into new forms.

- Final Application – The processed sponge is used in various industries such as furniture, automotive, and packaging.

Key Features of a Sponge Recycling Machine

- High-Efficiency Processing – Converts waste materials into reusable forms quickly.

- Automated System – Reduces labor requirements and enhances productivity.

- Versatile Output Options – Creates foam in different densities and shapes.

- Energy-Saving Design – Minimizes power consumption for cost-effective operation.

- Eco-Friendly Approach – Reduces landfill waste and promotes recycling initiatives.

Advantages of Using a Sponge Recycling Machine

- Significant Waste Reduction – Helps industries minimize foam waste.

- Lower Production Costs – Saves money by repurposing materials instead of purchasing new ones.

- Eco-Conscious Manufacturing – Supports sustainability goals and green production.

- Versatile Industry Applications – Used in furniture, automotive, packaging, and more.

- Regulatory Compliance – Helps businesses adhere to waste management and recycling standards.

Industries That Benefit from Sponge Recycling Machines

A sponge recycling machine is essential for various industries, including:

- Furniture Manufacturing – Creating recycled foam for cushions and padding.

- Automotive Sector – Producing seat cushions and insulation materials.

- Packaging Industry – Manufacturing protective packaging from repurposed sponge.

- Construction & Insulation – Using recycled foam for soundproofing and thermal insulation.

- Mattress Production – Developing eco-friendly mattress components from recycled sponge.

Choosing the Right Sponge Recycling Machine

When selecting a sponge recycling machine, consider these factors:

- Processing Capacity – Match the machine’s capacity with your recycling needs.

- Automation Features – Decide between semi-automated and fully automated models.

- Energy Efficiency – Opt for a machine that operates with minimal power consumption.

- Output Customization – Ensure the machine can produce various foam densities and sizes.

- Manufacturer Reliability – Choose a supplier that offers strong customer support and maintenance services.

Top Manufacturers of Sponge Recycling Machines

Leading companies providing high-performance sponge recycling machines include:

- SR Foam Machinery – Renowned for durable and efficient recycling solutions.

- Sunkist Machinery – Specializing in advanced foam processing technology.

- Sabtech Machines – Offering innovative solutions for foam recycling.

- Santech Industries – Providing reliable and energy-efficient foam recycling machines.

Conclusion

Investing in a sponge recycling machine is a smart move for businesses looking to improve sustainability while reducing costs. By repurposing foam waste, industries can promote environmentally friendly practices while maintaining operational efficiency.

Enhance your production with an advanced sponge recycling solution from SR Foam Machinery and take the next step towards sustainable manufacturing.