Polyethylene (PE) bags, also known as PE liners, have become a vital component in various industries due to their versatility, durability, and cost-effectiveness. From packaging food and industrial products to protecting goods during transportation, PE bags serve a range of purposes in different sectors. As demand for sustainable and reliable packaging solutions increases, plastic bag manufacturers in Ahmedabad, Plastic bags manufacturers in Gujarat, and PE bag manufacturers in Ahmedabad play a pivotal role in supplying high-quality PE bags to both domestic and international markets.

In this article, we will explore the types, benefits, and applications of PE bags and PE liners, as well as the contributions of manufacturers in Ahmedabad and Gujarat to the growing demand for these essential products.

What Are PE Bags and PE Liners?

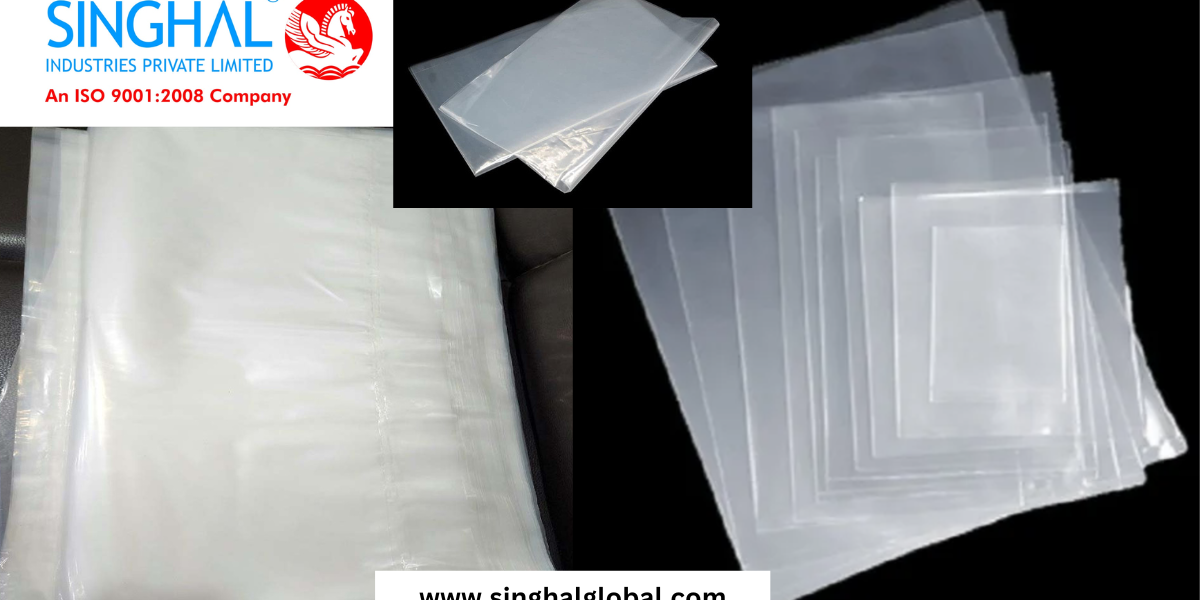

PE bags, made from polyethylene, are flexible, lightweight, and durable packaging solutions widely used for various purposes. They come in different thicknesses and sizes, providing solutions for everything from food packaging to industrial storage needs. PE liners, on the other hand, are a specialized type of PE bag, typically used for lining containers, tanks, or bins to prevent leakage and contamination.

Polyethylene, a widely used plastic, offers excellent strength and protection against moisture, dust, and other external factors, making PE bags ideal for packaging and transportation. The material’s ability to be molded into different shapes, sizes, and thicknesses adds to its versatility.

Applications of PE Bags and PE Liners

1. Food Packaging

One of the most common uses of PE bags is in food packaging. These bags offer excellent protection for food products, ensuring freshness while also being safe for direct contact with food. PE bags are often used to package snacks, grains, frozen food, vegetables, and bakery items. Their ability to provide an airtight seal helps preserve the quality of the products inside.

In addition to food packaging, PE liners are also used in the food industry to line containers or bins, ensuring that liquids and oils do not leak out and contaminate other items.

2. Industrial Packaging

PE bags are also heavily utilized in the industrial sector for packaging materials such as chemicals, fertilizers, and construction materials. These bags provide a reliable, cost-effective solution for safely storing and transporting bulk products. The durability and resistance of PE bags to moisture and environmental elements ensure that the goods inside remain safe and intact during transit.

For larger or heavier items, PE liners are often used inside industrial bins and containers to prevent any spillage or contamination.

3. Retail and Consumer Goods

In the retail sector, PE bags are commonly used for packaging a wide range of products, including clothing, electronics, toys, and personal care items. PE bags are lightweight yet strong, making them an ideal packaging solution for items that need to be stored, transported, or sold in stores. Custom printed PE bags with branding and logos are popular in retail as they serve both a functional and marketing purpose.

4. Waste Management

PE bags are also essential in waste management applications. They are commonly used as trash liners in homes, offices, and industries. PE liners, in particular, are designed to line trash bins, dumpsters, and other waste storage containers to ensure that waste does not leak out. Their strong, flexible nature allows them to withstand the weight of heavy trash while preventing leaks or spills.

5. Agricultural Use

Agriculture is another sector where PE bags and liners play a key role. They are used to store seeds, fertilizers, and pesticides. Additionally, PE liners are often used to line silos or grain storage facilities to ensure that the contents remain free from moisture and pests. PE bags are also commonly used for packaging fresh produce, particularly for vegetables and fruits.

6. Shipping and Transportation

PE bags are frequently used in the shipping and transportation industry for protecting items during transit. Whether it’s clothing, electronics, or industrial equipment, PE bags provide protection against moisture, dirt, and physical damage. PE liners are also used to line shipping containers, ensuring that goods remain secure and protected from the elements during long journeys.

Benefits of PE Bags and PE Liners

1. Durability and Strength

PE bags are renowned for their strength and durability. They are resistant to tears, punctures, and abrasion, making them ideal for packaging and storing a wide range of products. Their robust nature ensures that they can withstand rough handling and transportation, making them a reliable packaging solution.

2. Cost-Effectiveness

PE bags are a cost-effective packaging solution compared to other alternatives like paper or glass. Their lightweight nature reduces shipping costs, and the ability to mass-produce them ensures that they are affordable for businesses across various industries. This makes PE bags an economical choice for packaging and protective purposes.

3. Water and Moisture Resistance

One of the primary advantages of PE bags is their resistance to water and moisture. PE material is non-porous, meaning it does not allow moisture to seep through. This makes PE bags an excellent option for packaging food products, chemicals, and other items that need to be protected from environmental factors during storage and transit.

4. Versatility

PE bags come in various sizes, thicknesses, and shapes, making them incredibly versatile. They can be customized to suit different applications, from small bags for retail to large bags for industrial use. The flexibility of the material allows it to be used for a wide range of packaging and storage needs.

5. Sustainability

While plastic bags have often been criticized for their environmental impact, PE bags are more environmentally friendly than many other types of plastic. They are recyclable and can be reused in many applications. Additionally, efforts to develop biodegradable PE films have made the material more sustainable, offering a more eco-conscious option for packaging.

The Role of Plastic Bag Manufacturers in India

India is home to a robust manufacturing industry that produces a wide range of plastic products, including PE bags and liners. Plastic bag manufacturers in Ahmedabad, plastic bags manufacturers in Gujarat, and PE bag manufacturers in Ahmedabad are key players in meeting the demand for PE bags and liners both domestically and internationally.

Plastic Bag Manufacturers in Ahmedabad

Ahmedabad, one of the major industrial hubs in Gujarat, is home to several leading plastic bag manufacturers. These manufacturers specialize in producing high-quality PE bags that meet global standards and cater to industries ranging from food packaging to waste management. They utilize advanced manufacturing technologies and high-quality raw materials to produce durable and reliable products.

Plastic Bags Manufacturers in Gujarat

Gujarat, with its thriving manufacturing sector, is home to numerous plastic bags manufacturers who cater to both domestic and international markets. The state’s strategic location, coupled with its infrastructure, enables manufacturers to efficiently distribute PE bags and liners to customers worldwide.

PE Bag Manufacturer in Ahmedabad

The PE bag manufacturers in Ahmedabad are particularly known for their ability to provide customized solutions for their clients. Whether it’s tailored sizes, thicknesses, or branding on the bags, manufacturers in Ahmedabad offer versatility to meet specific customer needs. Their focus on quality and cost-effectiveness makes them a go-to source for businesses in need of reliable PE bags.

Factors Affecting the Price of PE Bags

The price of PE bags and liners can vary depending on several factors, including:

-

Size and Thickness: Larger bags or those with thicker material will generally be more expensive.

-

Quantity: Bulk orders often result in reduced per-unit costs, making larger purchases more affordable.

-

Customization: Bags with specific customizations, such as printed logos or specialized features (e.g., UV resistance), may come at a higher price.

-

Raw Material Costs: Fluctuations in the cost of polyethylene can impact the overall price of PE bags.

Summary

PE bags and PE liners have become indispensable tools in a variety of industries due to their durability, cost-effectiveness, and versatility. From food packaging to industrial uses, these bags offer reliable protection and storage solutions. Plastic bag manufacturers in Ahmedabad, plastic bags manufacturers in Gujarat, and PE bag manufacturers in Ahmedabad are crucial in providing high-quality products that meet global standards. As industries continue to demand efficient packaging solutions, PE bags remain an essential product that businesses trust for packaging, protecting, and transporting goods.

FAQs About PE Bags and PE Liners

1. What are the main uses of PE bags?

PE bags are used in various industries, including food packaging, retail packaging, waste management, agriculture, and shipping. They provide an effective and cost-efficient solution for packaging, protecting, and transporting goods.

2. Are PE bags recyclable?

Yes, PE bags are recyclable and can be reused in various applications. Many manufacturers are also working towards developing biodegradable PE bags to reduce the environmental impact of plastic waste.

3. How durable are PE bags?

PE bags are known for their durability and resistance to tearing, puncturing, and abrasion. They are designed to withstand rough handling, making them ideal for packaging and transportation.