Polycarbonate (PC) hollow sheets have emerged as one of the most popular materials in the construction, agriculture, and industrial sectors due to their durability, insulation properties, and versatility. Made from high-performance polycarbonate resin, these sheets are lightweight yet highly durable, offering a combination of strength, thermal insulation, and UV protection. Their unique structure, which consists of hollow channels between layers, contributes to their strength and insulating properties. In this Pulkit Plastic Products, we explore the features, benefits, applications, and market trends related to hollow polycarbonate sheets, with a special emphasis on their role in various industries and their advantages over other materials.

What Are PC Hollow Sheets?

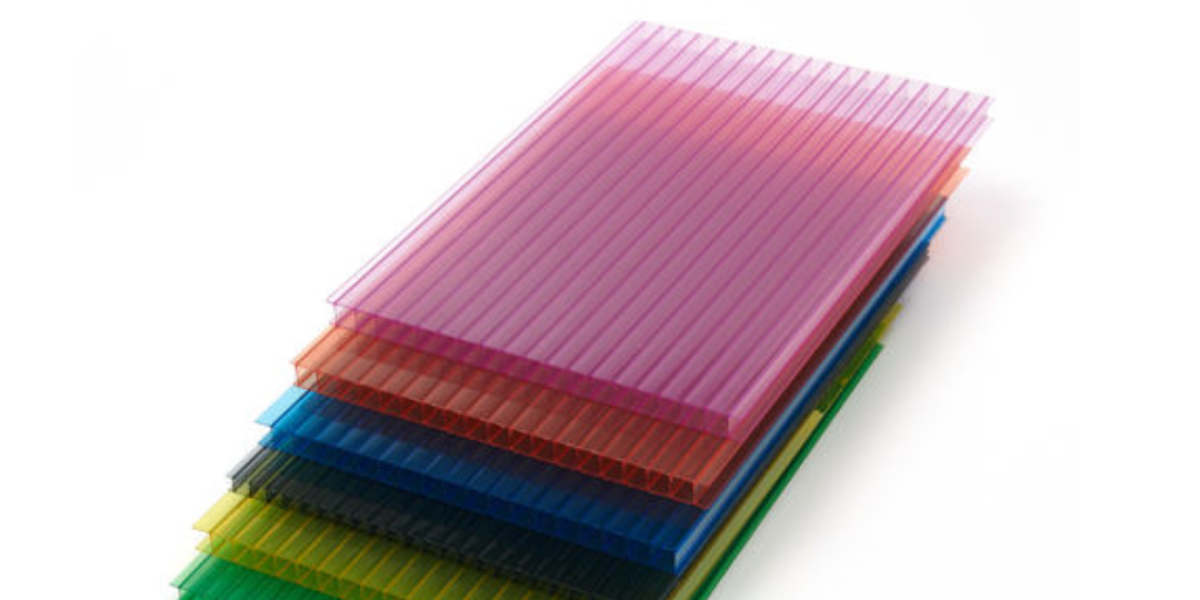

PC hollow sheets, also known as hollow polycarbonate sheets or hollow sheet polycarbonate, are a type of multi-layered plastic sheet made from polycarbonate resin. These sheets are engineered with hollow channels between layers, which provide significant strength and rigidity without adding much weight. The hollow structure makes them excellent at providing insulation and energy efficiency, as the air trapped in the channels acts as an insulator. Polycarbonate, a thermoplastic polymer, is known for its high impact resistance, making it a preferred choice for many applications that require durability and safety.

The polycarbonate material used in hollow sheets is known for its exceptional optical clarity, weather resistance, and UV protection. These features make PC hollow sheets highly effective in both outdoor and indoor environments, where exposure to the elements can lead to material degradation. The lightweight yet strong nature of these sheets makes them a preferred option for a wide variety of construction and industrial uses.

Key Benefits of PC Hollow Sheets

One of the major reasons for the increasing popularity of Hollow polycarbonate sheet is the range of benefits they offer. These include:

- Lightweight Yet Strong: The hollow channels within the sheet reduce its overall weight without compromising its strength and rigidity. This makes polycarbonate hollow sheets easy to handle, transport, and install, all while maintaining excellent structural integrity.

- Thermal Insulation: The hollow structure of the sheets acts as a natural insulator, helping to regulate temperature and reduce energy costs. This makes them ideal for use in greenhouses, skylights, and other applications where temperature control is critical.

- UV Protection: Polycarbonate sheets are inherently UV resistant, which means they can block harmful UV rays while allowing natural light to pass through. This feature helps protect plants in agricultural applications and ensures that interiors remain well-lit without being exposed to damaging UV radiation.

- Impact Resistance: Polycarbonate is known for its high impact resistance, making hollow polycarbonate sheets incredibly durable and able to withstand harsh weather conditions. They are virtually unbreakable, offering superior protection in environments where glass or acrylic sheets might break easily.

- Optical Clarity: Polycarbonate is known for its transparency and optical clarity, which means that the sheets can transmit light while maintaining high visibility. This makes them suitable for a variety of applications that require clear, bright environments, such as skylights, roof panels, and facades.

- Weather Resistance: Hollow polycarbonate sheets are designed to withstand extreme weather conditions, including rain, snow, and wind. Their ability to endure harsh environmental conditions makes them a reliable option for outdoor installations and structures.

- Eco-Friendly: Polycarbonate is a recyclable material, making these sheets an environmentally friendly option. Their energy-saving properties, combined with their long lifespan, contribute to sustainability in construction and industrial applications.

Common Applications of PC Hollow Sheets

The versatility of hollow polycarbonate sheets makes them suitable for a wide variety of applications. Some of the most common uses include:

- Roofing and Skylights: One of the most common applications for polycarbonate hollow sheets is in roofing and skylight installations. These sheets provide excellent light transmission while offering superior insulation and UV protection. They are ideal for creating energy-efficient roof panels that allow natural light to enter while keeping the interior temperature stable.

- Greenhouses: PC hollow sheets are widely used in the agricultural sector, particularly in greenhouse construction. The sheets’ insulation properties help maintain a stable temperature inside the greenhouse, which is essential for optimal plant growth. The UV protection feature also shields plants from harmful rays, allowing them to thrive in a controlled environment.

- Facades and Partitions: Polycarbonate hollow sheets are used in the construction of building facades and partitions. Their impact resistance and weatherproof qualities make them a durable choice for both indoor and outdoor partitioning. Additionally, their light transmission capabilities enhance the aesthetic appeal of modern buildings.

- Sheds and Canopies: Polycarbonate hollow sheets are frequently used in the construction of outdoor sheds, canopies, and shelters. Their ability to provide natural light, combined with their resistance to extreme weather conditions, makes them an excellent material for protecting outdoor spaces.

- Signs and Displays: Polycarbonate hollow sheets are used in the creation of signs and displays due to their clarity, strength, and durability. They are often employed in applications requiring both visibility and resistance to outdoor elements, such as outdoor advertisements and informational displays.

- Indoor and Outdoor Partitions: The aesthetic quality, coupled with the strength and insulating properties of polycarbonate, makes hollow sheets ideal for both indoor and outdoor partitions. These sheets are often used in office spaces, commercial buildings, and residential settings to create effective and attractive partitions.

- Carports and Parking Structures: Polycarbonate hollow sheets are ideal for use in carports and parking structures. Their ability to block UV rays while providing adequate lighting and weather protection makes them a popular choice for outdoor vehicle shelters.

Market Trends and Dynamics for Polycarbonate Hollow Sheets

The market for Hollow sheet polycarbonate is expected to grow steadily due to increasing demand across various sectors. The demand for energy-efficient and sustainable building materials has driven the popularity of polycarbonate hollow sheets, particularly in the construction and agricultural industries.

The construction sector, in particular, is expected to be a major driver of growth for polycarbonate hollow sheets, as these materials provide cost-effective, lightweight, and durable alternatives to glass and other traditional building materials. Additionally, the rising focus on green building initiatives and energy efficiency is expected to continue boosting the demand for polycarbonate sheets in the coming years.

The agricultural industry, with its growing need for temperature regulation and protection from UV rays, is another significant market for polycarbonate hollow sheets. Greenhouses, which require materials that offer both strength and light diffusion, are a prime application for these sheets.

In terms of geographic trends, polycarbonate hollow sheet suppliers in Asia, particularly in countries like China, India, and South Korea, are expected to benefit from the growing demand in both domestic and international markets. These regions have well-established manufacturing capabilities, making them key players in the global supply chain.

Challenges in the PC Hollow Sheet Market

While polycarbonate hollow sheets offer numerous benefits, there are some challenges that manufacturers and suppliers must address. One of the key challenges is the initial cost of polycarbonate sheets, which can be higher than other plastic or glass materials. However, the long-term benefits, such as energy savings and durability, often offset the initial investment.

Another challenge is the potential for surface damage. Although polycarbonate is highly impact-resistant, it is still susceptible to scratches and other types of surface degradation if not properly maintained or protected during installation.

Moreover, the market for polycarbonate hollow sheets faces competition from alternative materials, such as acrylic and glass. Manufacturers must continuously innovate to improve the performance and cost-effectiveness of polycarbonate sheets to maintain their competitive edge.

Conclusion: The Future of Polycarbonate Hollow Sheets

The Polycarbonate hollow sheets have proven to be a highly versatile and durable material, offering a wide range of benefits for both residential and commercial applications. Their strength, insulation properties, and UV resistance make them ideal for a variety of uses, from roofing and skylights to agricultural greenhouses and outdoor canopies. As demand for energy-efficient, sustainable building materials continues to rise, polycarbonate hollow sheets are expected to see steady growth in the coming years.

The ability to provide natural light while offering thermal insulation and protection from UV rays makes these sheets a valuable option for industries focused on sustainability and energy efficiency. Despite the challenges faced by the market, the ongoing innovation and demand for polycarbonate hollow sheets suggest a promising future for this material.

Frequently Asked Questions (FAQs)

1. What is the difference between polycarbonate hollow sheets and regular polycarbonate sheets?

Polycarbonate hollow sheets feature hollow channels between layers, providing better thermal insulation and strength-to-weight ratio compared to solid polycarbonate sheets. This unique structure makes hollow sheets more suitable for applications that require energy efficiency, impact resistance, and light diffusion.

2. Can polycarbonate hollow sheets be used in extreme weather conditions?

Yes, polycarbonate hollow sheets are designed to withstand extreme weather conditions, including heavy rain, snow, and high winds. Their impact resistance and UV protection make them ideal for outdoor applications, such as roofing, facades, and agricultural uses.

3. Are polycarbonate hollow sheets recyclable?

Yes, polycarbonate is a recyclable material, making hollow polycarbonate sheets an environmentally friendly option for construction and industrial applications. Recycling polycarbonate sheets reduces waste and helps conserve resources.

4. How do polycarbonate hollow sheets contribute to energy efficiency?

Polycarbonate hollow sheets provide excellent insulation, reducing heat transfer and helping to maintain stable indoor temperatures. This energy-efficient property makes them ideal for reducing heating and cooling costs in buildings and agricultural structures.