Metal Forming Machine Tools Market Outlook

The global metal forming machine tools market is expected to grow at a compound annual growth rate (CAGR) of 4% between 2025 and 2034. As industries worldwide continue to advance in precision engineering and automation, the demand for metal forming machine tools is expected to increase. These tools, essential in shaping and processing metal materials, are widely used in industries like automotive, general machinery, precision engineering, and transport machinery. The market is driven by technological advancements in machine tools, increased demand for high-quality products, and the expansion of end-user industries.

The need for cost-efficient, precise, and versatile manufacturing processes continues to fuel the adoption of metal forming machine tools, particularly in emerging economies where industrialization and manufacturing growth are rapidly progressing.

Metal Forming Machine Tools Market Trends

Several key trends are shaping the global metal forming machine tools market, driven by technological innovations, increasing industrial demands, and regional growth in manufacturing industries:

- Adoption of Computerized Numerical Control (CNC): CNC technology is revolutionizing the metal forming machine tools market by providing higher precision, faster production speeds, and reduced human error. As industries demand more automation and higher productivity, CNC machines are replacing conventional machines in many applications. This trend is expected to drive further growth in the CNC segment.

- Focus on Automation and Industry 4.0: Industry 4.0 is characterized by smart manufacturing, which integrates data analytics, IoT, and AI. Manufacturers are increasingly implementing automation in metal forming processes, enhancing efficiency and reducing operational costs. This transition to automated processes is driving the demand for more advanced machine tools that can be integrated into smart factories.

- Increased Demand for Precision Engineering: With industries focusing on producing high-quality, intricate parts and components, particularly in automotive and aerospace sectors, the demand for precision engineering is growing. Metal forming machines, including bending, forging, and shearing machines, are essential in achieving the required tolerances and product specifications.

- Sustainability and Eco-Friendly Solutions: As sustainability becomes a key focus for industries, manufacturers are looking for machine tools that reduce waste, energy consumption, and carbon footprints. Eco-friendly machine tools that comply with environmental regulations are gaining traction, particularly in developed regions where stringent environmental policies are enforced.

- Growth in Emerging Markets: As industrialization accelerates in emerging economies, such as India and China, the demand for metal forming machine tools is rising. These countries are rapidly expanding their manufacturing sectors, especially in automotive, general machinery, and transport machinery applications, creating significant growth opportunities for machine tool manufacturers.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/metal-forming-machine-tools-market/requestsample

Metal Forming Machine Tools Market Growth

The global metal forming machine tools market is expected to grow at a CAGR of 4% from 2025 to 2034. Several factors contribute to this growth:

- Increasing Industrialization and Manufacturing in Emerging Markets: As countries like India and China continue to experience rapid industrialization, the demand for metal forming machines is rising. These regions are seeing increased investments in infrastructure, automotive manufacturing, and machinery, driving the growth of the metal forming machine tools market.

- Technological Advancements: The integration of advanced technologies like CNC, robotics, and artificial intelligence (AI) into metal forming processes is driving productivity and improving the precision of manufactured components. This is making machine tools more efficient and cost-effective, contributing to market expansion.

- Rising Demand for Customization in Manufacturing: With industries pushing for more customized and complex products, manufacturers are investing in advanced metal forming machine tools to meet the specific needs of their customers. This customization trend is particularly prevalent in industries like automotive, aerospace, and precision engineering.

- Focus on Quality and Efficiency in Manufacturing: As businesses face increasing pressure to improve product quality while reducing costs, metal forming machines are becoming more essential. These tools allow for faster, more accurate, and more efficient production processes, leading to reduced scrap rates and improved product quality.

- Expanding Applications in Various Industries: The automotive, aerospace, and machinery sectors are among the largest consumers of metal forming machine tools. With increasing demand for lightweight and fuel-efficient vehicles and components, as well as high-precision parts for aerospace, the need for advanced metal forming technologies continues to rise.

Market Segmentation

The global metal forming machine tools market can be segmented based on technology, product, application, and region. These segments offer valuable insights into market dynamics and consumer demands.

1. Breakup by Technology:

- Computerized Numerical Control (CNC): CNC technology is the leading segment, providing high precision, versatility, and automation in metal forming processes. CNC machines are used in a wide range of applications, including automotive, aerospace, and precision engineering, due to their ability to handle complex and intricate designs.

- Conventional: Conventional machines, which rely on manual controls, are still used in smaller-scale operations or for specific applications that do not require the precision or automation provided by CNC machines. While their usage is decreasing, they remain relevant in certain market segments.

2. Breakup by Product:

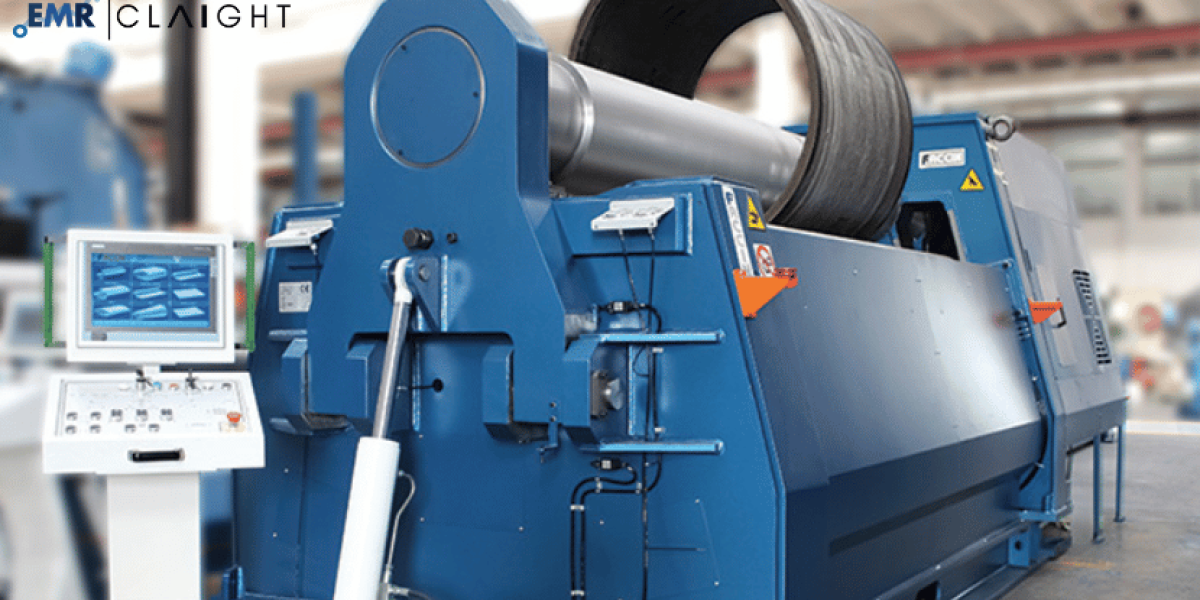

- Rolling Mill Machines: Rolling mill machines are widely used in the production of metal sheets, strips, and plates. These machines are critical in industries like steel production, where the shaping of metal materials is essential to the manufacturing process.

- Bending Machines: Bending machines are used to form metal into desired shapes by applying force to bend the material. These machines are commonly used in the production of components for various industries, including automotive and construction.

- Hydraulic Presses: Hydraulic presses are used for metal forming processes that involve high pressure, such as stamping, forging, and molding. These presses are essential in applications like automotive manufacturing and precision metalworking.

- Mechanical Presses: Mechanical presses are used in metal forming processes that require high-speed operations. These presses are typically used in industries like automotive and general machinery to create parts with precise dimensions.

- Shearing Machines: Shearing machines are used to cut or shear metal sheets into specific sizes or shapes. These machines are widely used in industries such as construction, automotive, and general machinery.

- Forging Machines: Forging machines are used to shape metal by applying compressive force, typically at high temperatures. These machines are essential in the automotive and aerospace sectors, where strength and durability are critical.

- Wire Forming Machines: Wire forming machines are used to create various wire products, such as springs, clips, and fasteners. These machines are widely used in industries like automotive, electronics, and manufacturing.

- Others: This category includes specialized machines used for specific metal forming processes, such as spinning, casting, and extrusion.

3. Breakup by Application:

- Automotive: The automotive industry is one of the largest consumers of metal forming machine tools, as these tools are essential for manufacturing vehicle components such as body panels, chassis, and engine parts.

- General Machinery: General machinery manufacturing, including the production of industrial machines and components, requires advanced metal forming machines for precise manufacturing processes.

- Precision Engineering: Precision engineering involves the production of highly accurate and intricate components, such as medical devices, electronics, and aerospace parts. Metal forming machine tools are essential in achieving the high levels of precision required in this sector.

- Transport Machinery: The transport machinery sector, including the production of railway and aircraft components, relies heavily on metal forming machines to produce strong and durable parts.

- Others: Other sectors that use metal forming machines include energy, construction, and electronics, where metal forming processes are critical for producing structural components and equipment.

4. Breakup by Region:

- North America:

- United States of America: The U.S. is a major market for metal forming machine tools, driven by strong demand from the automotive, aerospace, and general machinery sectors.

- Canada: Canada also contributes significantly to the growth of the market, with increased demand for high-precision and automated metal forming machines.

- Europe:

- United Kingdom, Germany, France, Italy: Europe is a key market for metal forming machine tools, particularly in countries like Germany and Italy, which have strong automotive, aerospace, and machinery industries.

- Asia Pacific:

- China, Japan, India: Asia Pacific is the largest market for metal forming machines, driven by rapid industrialization and the strong presence of automotive, electronics, and manufacturing industries in China, Japan, and India.

- Latin America:

- Brazil, Argentina, Mexico: Latin America is seeing increasing demand for metal forming machines due to the growth of manufacturing sectors, particularly in automotive and general machinery.

- Middle East and Africa:

- Saudi Arabia, United Arab Emirates, Nigeria, South Africa: The Middle East and Africa are emerging markets for metal forming machines, with increasing investments in infrastructure and industrial development.

Market Key Players

Leading players in the global metal forming machine tools market include:

- Mitsubishi Material Corporation

- Amada Co., Ltd.

- Komatsu Ltd.

- Machine Tools (India) Limited

- Schuler AG

- Others

These companies are focusing on innovation, automation, and providing high-quality products to cater to the growing demand for advanced metal forming solutions across various industries.

Media Contact:

Company Name: Claight Corporation

Contact Person: Eren smith, Corporate Sales Specialist – U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com