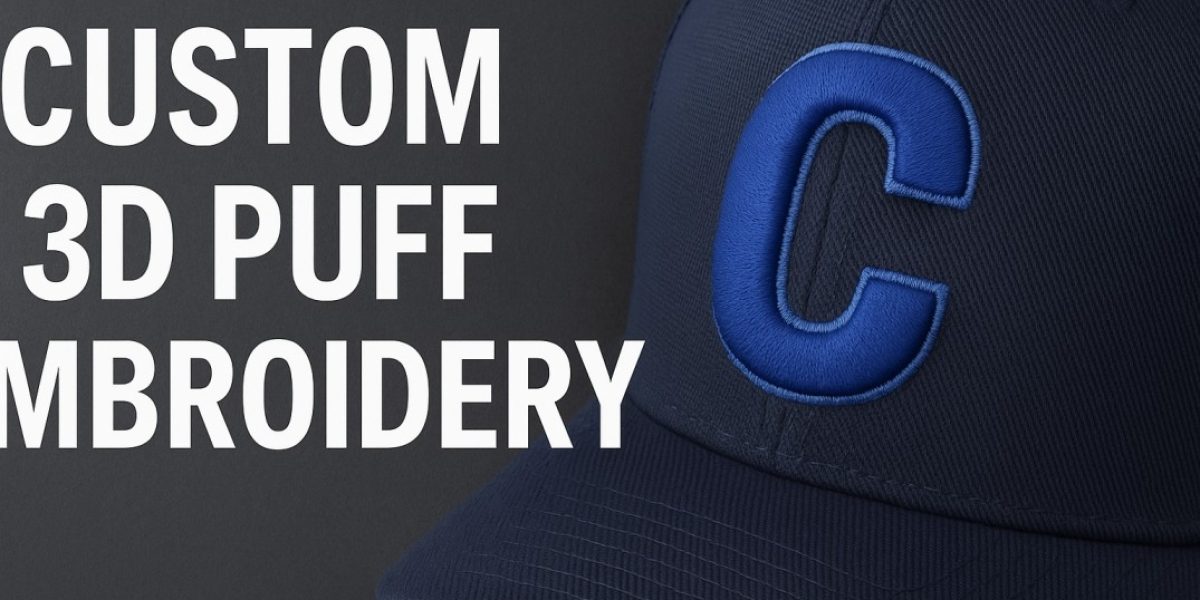

What is 3D Puff Embroidery?

3D puff embroidery is a high-impact embroidery technique where foam is inserted under the top stitching to create a raised, three-dimensional look. It is most commonly used for headwear, especially snapbacks, fitted caps, and trucker hats, delivering a bold, standout effect that standard flat embroidery cannot match.

This technique is popular for logos, monograms, and bold fonts, offering an elevated texture and eye-catching appearance. The depth and texture of puff embroidery add a premium finish that resonates with streetwear, sports, and lifestyle brands alike.

Benefits of 3D Puff Embroidery on Hats

1. High Visual Impact

3D puff embroidery offers a raised, bold finish that commands attention. It’s perfect for branding, making company logos and emblems pop, especially on caps and promotional hats.

2. Enhanced Brand Perception

Adding dimensional depth to your logo elevates the perceived value of your merchandise. Brands that use custom 3D puff embroidery often appear more premium, established, and professional.

3. Long-Lasting and Durable

When done correctly, 3D puff embroidery is extremely durable, resistant to wear and tear, and maintains its shape through regular use and washing.

4. Customization Flexibility

From color combinations to font selection and placement, 3D puff embroidery allows for extensive customization, giving your hats a completely bespoke look.

How 3D Puff Embroidery Works

1. Designing for Puff Embroidery

Designing for puff embroidery requires specific attention. Not all designs translate well into 3D. Ideal designs are:

-

Bold and thick (minimum line thickness of 3mm)

-

Simple and clear

-

Limited in fine detail

Vector-based files such as .AI, .EPS, or .PDF are preferred, and text should be converted to outlines before submission.

2. Foam Insertion and Stitching

A layer of special embroidery foam is placed under the fabric where the 3D effect is desired. The embroidery machine then sews over the foam, compressing it and creating a raised effect. Excess foam is removed, and a heat process is often used to seal the design.

3. Equipment and Thread Considerations

Using high-quality thread such as polyester or rayon ensures longevity and vibrant color. Commercial-grade embroidery machines with 3D capabilities are a must for achieving clean and professional results.

Best Hats for 3D Puff Embroidery

The structure of the hat plays a crucial role in supporting the 3D embroidery. Recommended styles include:

-

Snapbacks: Flat brim and structured front ideal for large logos.

-

Fitted Hats: Premium quality with a seamless look.

-

Trucker Hats: Mesh back with a structured front, great for high-contrast designs.

-

Five-Panel Caps: Offer a modern look with ample space for embroidery.

Materials such as cotton twill, canvas, or polyester blends provide the best surface for a clean puff effect.

Design Tips for Maximum Impact

Keep it Simple

Intricate details may be lost in puff embroidery. Go for bold lines and minimalistic styles to maximize clarity.

Use Contrasting Colors

Contrast between the hat and thread colors increases visibility and makes the design stand out sharply.

Mind the Placement

Front center is the most popular placement, but side embroidery or even back puff detailing can add uniqueness to your design.

Pairing with Flat Embroidery

For complex designs, combining flat embroidery with puff can create a layered, multi-dimensional appearance that looks highly professional.

Common Mistakes to Avoid

-

Using fine lines or text: These won’t puff well and can lead to messy stitching.

-

Incorrect foam thickness: Using the wrong foam can distort the embroidery or make the design collapse.

-

Low-quality digitizing: Always use a digitizer experienced in puff embroidery. Incorrect stitch density or patterns will ruin the effect.

Digitizing for 3D Puff Embroidery

Digitizing is the most critical step in the embroidery process. The file must be specifically digitized for 3D puff, which means:

-

Creating a loose underlay to hold the foam

-

Adjusting stitch density and pattern

-

Adding cut lines to trim excess foam

Do not attempt to use a standard flat embroidery file for puff designs—it will not produce quality results.

Cost Factors and Pricing Considerations

The cost of custom 3D puff embroidery is typically higher than flat embroidery due to:

-

Increased stitch count

-

Foam material cost

-

Longer production time

-

Specialized digitizing

However, the impact and perceived value it adds to your product often justify the cost. Bulk orders may significantly reduce the per-piece cost.

Caring for 3D Puff Embroidered Hats

To ensure longevity:

-

Hand wash only or use a hat cleaning frame if machine washing

-

Avoid high heat (dryer or iron)

-

Do not wring or fold the embroidered area

-

Store caps on a hat rack or shelf to maintain shape

Industries Using 3D Puff Embroidery

Streetwear Brands

3D embroidery is synonymous with modern streetwear. Logos with depth create an unmistakable statement on bold cap designs.

Corporate Promotions

Companies utilize puff embroidery for premium giveaways and brand merch, aligning their image with quality and professionalism.

Sports Teams

Caps with team logos in puff embroidery create a strong identity and fan appeal, making them a staple in team merchandise.

Music and Entertainment

Artists and record labels often launch limited-edition merch with custom embroidered caps, enhancing their brand’s aesthetic and retail value.

Why Choose Custom 3D Puff Embroidery for Your Hats?

Whether you’re launching a new fashion line, promoting your business, or creating personalized merch, 3D puff embroidery ensures your hats are memorable, high-quality, and visually striking. With the right design, material, and production partner, puff embroidery can transform a simple cap into a standout branding tool.