In today’s fast-paced industrial landscape, conveyor systems are the backbone of efficient material handling. From manufacturing plants to warehouses, these systems ensure seamless movement of goods, reducing manual labor and boosting productivity. However, like any machinery, conveyors require regular upkeep to perform at their best. This is where Conveyor Maintenance comes into play. Proper care not only extends the lifespan of your conveyor system but also prevents costly downtime and repairs. In this blog post, we’ll dive into the essentials of Conveyor Belt Maintenance, offering practical tips to keep your operations running smoothly.

Why Conveyor Maintenance Matters

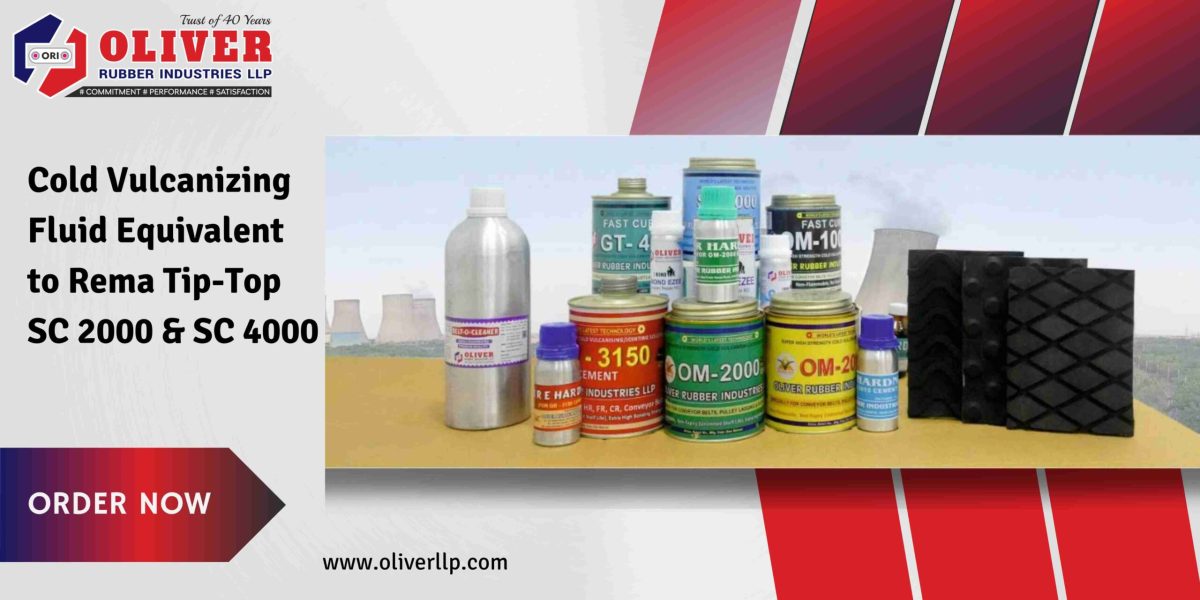

Conveyor systems operate under constant stress, handling heavy loads, abrasive materials, and varying environmental conditions. Without routine maintenance, wear and tear can lead to belt misalignment, roller failures, or even complete system breakdowns. For industries relying on rubber-based conveyor belts—such as those manufactured by Oliver Rubber LLP—maintaining the integrity of the belt is especially critical. At Oliver Rubber LLP, we take pride in being one of the foremost manufacturers of high-quality rubber sheets in India. Our expertise in producing durable, customizable rubber solutions ensures that your conveyor belts can withstand rigorous demands, provided they are well-maintained.

Neglecting Conveyor Maintenance can result in inefficiencies, safety hazards, and unplanned interruptions. By adopting a proactive approach, you can minimize these risks and maximize the return on your investment.

Key Components of Conveyor Maintenance

To understand Conveyor Belt Maintenance, it’s essential to know the key components of a conveyor system and how to care for them:

- Belt Inspection and Cleaning

The conveyor belt is the heart of the system. Regular inspections should focus on identifying cuts, tears, or signs of fraying. Dust, debris, and material buildup can also degrade the belt over time. Cleaning the belt with appropriate tools and solutions prevents slippage and ensures smooth operation. At Oliver Rubber LLP, we offer rubber sheets tailored to your conveyor’s specific needs—customizable in thickness, hardness, and dimensions—making them resilient to wear when properly maintained. - Roller and Pulley Checks

Rollers and pulleys support the belt and facilitate its movement. Over time, they can become misaligned or worn, causing the belt to drift or malfunction. Lubricating moving parts and replacing damaged rollers promptly are vital steps in Conveyor Maintenance. A well-aligned system reduces strain on the belt and enhances efficiency. - Tension Adjustment

Proper belt tension is crucial for optimal performance. Too much tension can strain the system, while too little can lead to slippage. Regularly check and adjust the tension according to the manufacturer’s guidelines to maintain balance. - Motor and Drive System Care

The motor and drive system power the conveyor. Listen for unusual noises, check for overheating, and ensure electrical components are functioning correctly. Routine lubrication and timely repairs keep these components in top shape.

Best Practices for Conveyor Belt Maintenance

Beyond inspecting individual parts, adopting best practices can elevate your Conveyor Maintenance efforts:

- Schedule Regular Inspections: Set a maintenance schedule based on your conveyor’s usage. Daily visual checks combined with weekly or monthly in-depth inspections can catch issues early.

- Train Your Team: Equip your staff with the knowledge to spot problems and perform basic upkeep. A trained team is your first line of defense against breakdowns.

- Use Quality Materials: The durability of your conveyor belt depends on the materials it’s made from. At Oliver Rubber LLP, we understand that every customer has unique requirements. That’s why we offer customizable solutions to tailor our rubber sheets according to your specific dimensions, thickness, hardness, and other parameters. Our commitment to excellence ensures you receive a product built to last.

- Keep Records: Document all maintenance activities, including repairs, replacements, and inspections. This helps track the system’s health and plan future upkeep.

Common Conveyor Maintenance Challenges

Even with the best intentions, challenges can arise during Conveyor Belt Maintenance. Abrasive materials may accelerate belt wear, while exposure to extreme temperatures can cause rubber to crack. Misalignment is another frequent issue, often stemming from uneven loads or faulty rollers. Addressing these challenges requires a combination of high-quality materials—like those from Oliver Rubber LLP—and diligent care.

The Role of Customization in Maintenance

Not all conveyors are created equal, and neither are their maintenance needs. A conveyor handling heavy industrial goods will require different care than one transporting lightweight packages. This is where customization shines. At Oliver Rubber LLP, our extensive range of rubber sheets caters to diverse applications across various sectors, including automotive, construction, industrial, and more. By tailoring the belt to your operational demands, you reduce wear and simplify maintenance.

The Bottom Line

Investing time and resources in Conveyor Maintenance is not just about fixing problems—it’s about preventing them. A well-maintained conveyor system enhances safety, efficiency, and longevity, delivering value to your business. Whether you’re running a small operation or a large-scale facility, the principles of Conveyor Belt Maintenance remain the same: inspect, clean, adjust, and replace as needed.

At Oliver Rubber LLP, we’re proud to support industries across India with top-tier rubber solutions. Our dedication to innovation and quality ensures that your conveyor belts are built to perform, provided you give them the care they deserve. So, take the first step today—assess your conveyor system, implement a maintenance routine, and watch your productivity soar.