Introduction to Polycarbonate Hollow Sheets

Polycarbonate hollow sheets, commonly referred to as hollow polycarbonate sheets, have become a game-changer in various industries due to their impressive combination of strength, lightweight properties, and versatility. Made from polycarbonate, a durable synthetic thermoplastic, these sheets are engineered to deliver exceptional performance in applications ranging from construction to signage. Understanding the features and benefits of hollow sheet polycarbonate can help businesses and consumers make informed decisions about the materials they choose for their projects.

The Pulkit Plastic Products are designed with internal air pockets that provide insulation, making them an ideal choice for applications requiring thermal efficiency. Additionally, these sheets are favored for their resistance to UV radiation, impact, and varying weather conditions. The result is a robust and reliable material that maintains functionality without compromising aesthetics. As we explore the various facets of polycarbonate hollow sheets, it becomes clear why they are increasingly being integrated into modern construction designs and consumer products.

Composition and Manufacturing Process of PC Hollow Sheets

The manufacturing process of polycarbonate hollow sheets begins with the polymerization of bisphenol A and phosgene, which creates polycarbonate resin. This resin is melted and extruded through specially designed dies that allow for the formation of hollow structures. The resulting sheets feature multiple layers with internal voids, a design that enhances thermal insulation and impact resistance.

This innovative design not only contributes to the material’s strength but also significantly reduces its weight compared to solid polycarbonate sheets. The sheets can also be fabricated in various thicknesses and sizes to accommodate different applications, providing versatility that is hard to match. The finishing touches may include UV coatings to enhance weather resistance and aesthetic appeal, further expanding the range of potential uses for these exceptional materials.

Advantages of Using Polycarbonate Hollow Sheets

One of the most compelling reasons for choosing Hollow sheet polycarbonate is their exceptional strength-to-weight ratio. These sheets deliver robust performance while remaining lightweight, making them easier and more cost-effective to transport and install. This property is particularly beneficial in construction projects where weight restrictions are a crucial consideration. Additionally, the high impact resistance of polycarbonate ensures that the sheets can withstand significant stresses without breaking or shattering, making them suitable for safety applications.

Another significant advantage is thermal insulation. The hollow structure of the sheets allows for better thermal regulation, minimizing heat transfer between the interior and exterior environments. This feature enhances energy efficiency in buildings, helping to reduce heating and cooling costs. Moreover, the lightweight nature of polycarbonate hollow sheets does not compromise their ability to block harmful UV radiation, protecting indoor spaces and occupants from sun damage while preserving the integrity of furniture and finishes.

Applications of PC Hollow Sheets

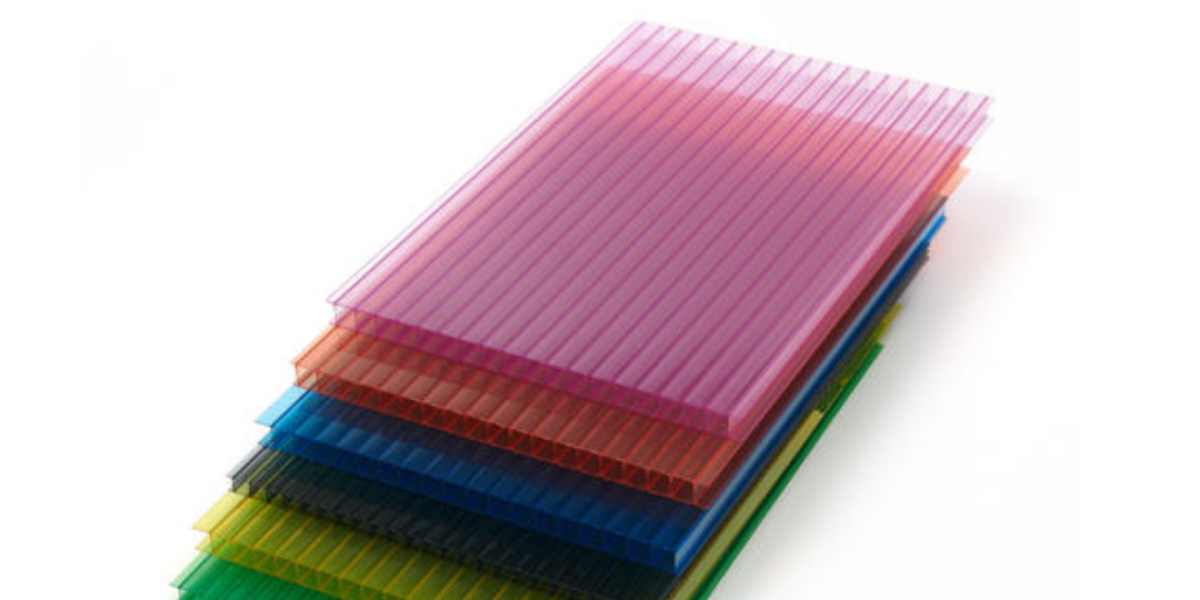

Hollow sheet polycarbonate is favored across a variety of sectors due to its many benefits. In construction, these sheets are often used for roofing systems, skylights, and greenhouse panels. Their insulating properties and ability to allow natural light while blocking UV rays make them ideal for creating bright and energy-efficient indoor environments. Additionally, architects appreciate the aesthetic versatility of polycarbonate sheets, as they can be produced in various colors and finishes, allowing them to blend seamlessly into a range of design styles.

Beyond construction, hollow polycarbonate sheets find applications in signage, protective barriers, and displays. Their lightweight and durable characteristics make them perfect for outdoor signs that need to withstand the elements while maintaining visibility and clarity. In the automotive industry, polycarbonate hollow sheets are used in applications such as vehicle glazing and protective panels, providing safety and aesthetics for both commercial and consumer vehicles. Their versatility extends to the leisure industry, where they are utilized in recreational structures, including water parks and sports facilities.

Environmental Benefits and Sustainability

As sustainability becomes an increasingly important consideration across industries, polycarbonate hollow sheets offer eco-friendly benefits that enhance their appeal. Many manufacturers prioritize environmentally responsible practices by ensuring that their polycarbonate products are recyclable at the end of their life cycle. This characteristic aligns with the increasing industry shift towards more sustainable building materials and practices.

Furthermore, the energy efficiency provided by Polycarbonate hollow sheet contributes positively to environmental sustainability. Better thermal insulation means reduced energy consumption for heating and cooling, which in turn lowers greenhouse gas emissions related to building operation. When combined with the longevity and durability of these sheets, the overall impact on resources is significantly lessened compared to traditional materials that may require more frequent replacements.

Installation and Maintenance

Installing polycarbonate hollow sheets requires careful consideration and adherence to manufacturer guidelines to ensure durability and performance. Depending on the application, these sheets can be installed using various methods, including framing, adhesive bonding, or employing fastening systems that prevent movement while allowing for thermal expansion and contraction.

Maintenance is relatively straightforward, requiring regular cleaning and inspection to ensure that the sheets remain clear and free of debris. Polycarbonate is inherently resistant to low temperatures and impacts, but it is advisable to avoid abrasive cleaning materials that could scratch the surface. For most applications, periodic washing with a mild soap and water solution will suffice to maintain the sheets’ clarity and functionality over time.

Cost-Effectiveness of Hollow Polycarbonate Sheets

The initial investment in polycarbonate hollow sheets may be higher than that of traditional materials like glass or acrylic, but when considering the total cost of ownership, hollow polycarbonate sheets often present better value. These sheets’ durability, combined with their energy-efficient properties, means that over time, users will benefit from reduced maintenance and replacement costs. In addition, the lightweight nature of these sheets can lower installation costs due to the decreased structural support required.

When assessing the long-term financial implications, the energy savings achieved through improved insulation and the potential for tax incentives related to energy-efficient building materials can further enhance the overall cost-effectiveness of polycarbonate hollow sheets. Industries that adopt this material may find that it aligns with their sustainability goals while also positively affecting their bottom line.

Conclusion

In conclusion, Hollow polycarbonate sheet represent a significant advancement in materials technology, providing unparalleled advantages in strength, insulation, and versatility. Their applications span across various industries, with benefits that extend from construction to signage and automotive uses. As the world shifts towards more sustainable practices, the eco-friendly characteristics of hollow polycarbonate sheets position them as a preferred choice for future projects. Understanding the properties and potential of these sheets will empower architects, builders, and consumers to make informed decisions, fostering innovation and sustainability in design and construction.

Frequently Asked Questions (FAQs)

- What are polycarbonate hollow sheets made of?

Polycarbonate hollow sheets are made from polycarbonate resin, which undergoes a manufacturing process that involves melting and extruding the resin into sheets with internal voids for optimal insulation and strength. - What are the advantages of using hollow polycarbonate sheets in construction?

Hollow polycarbonate sheets are lightweight, strong, and provide excellent thermal insulation while allowing natural light to pass through. They also block harmful UV rays, contributing to energy efficiency and protecting interiors. - Can hollow sheet polycarbonate be recycled?

Yes, many polycarbonate hollow sheets are recyclable. Manufacturers are increasingly adopting environmentally responsible practices that facilitate recycling, making them a sustainable choice for construction and other applications. - How do I maintain and clean polycarbonate hollow sheets?

Maintenance is simple; regular cleaning with a mild soap solution and soft cloth is generally sufficient. It’s important to avoid abrasive materials to prevent scratching the surface and to follow manufacturer guidelines for specific maintenance practices.