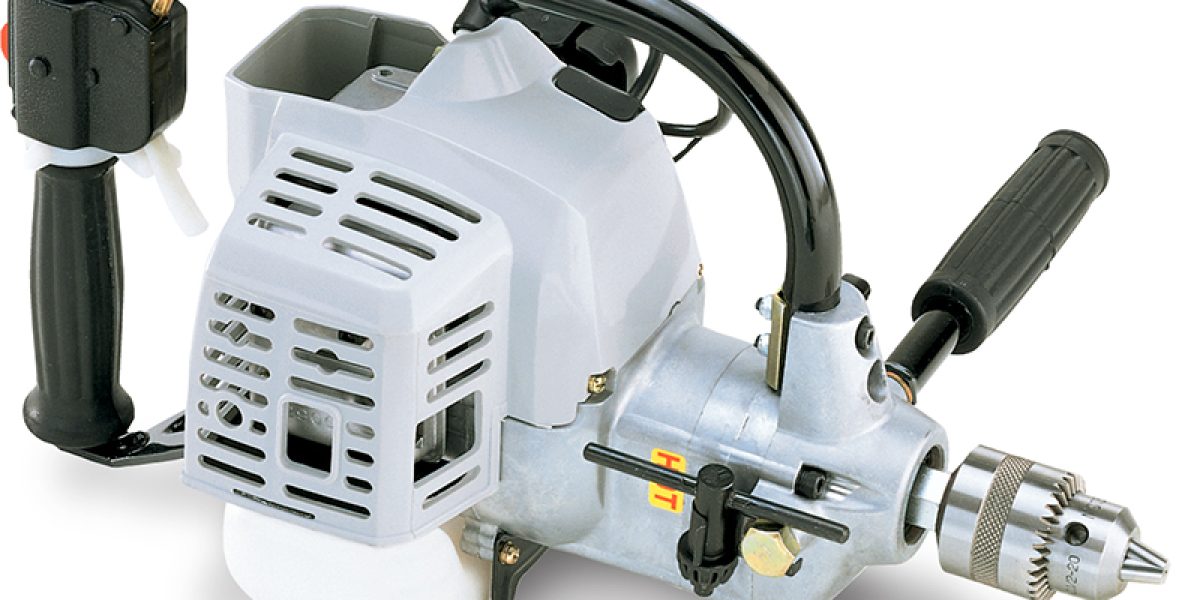

When it comes to achieving unparalleled efficiency in construction, woodworking, or home improvement projects, few tools rival the reliability and power of a gas powered drill . Known for its robust performance and ability to tackle challenging tasks, this tool is indispensable for professionals and DIY enthusiasts alike. Its strength lies not only in its engineering but also in the unique versatility it offers, making it a cornerstone in various industries.

The Evolution of Drilling Tools

Drills have come a long way from their humble beginnings. The journey started with hand-powered tools that required physical exertion and progressed to electric drills that revolutionized speed and convenience. However, gas-powered drills have carved out a special niche. Powered by internal combustion engines, these drills provide the muscle needed for tasks that electric drills often struggle with, such as breaking through dense materials or enduring long hours of operation.

Why Choose a Gas-Powered Drill?

The gas-powered drill is often chosen for its unmatched power and portability. Its combustion engine generates torque levels that electric drills cannot easily achieve, making it perfect for drilling through tough surfaces like reinforced concrete, hard soil, or dense wood. Additionally, because it doesn’t rely on electrical power, it can be used in remote locations or outdoor job sites where electrical outlets are unavailable. This versatility makes it an invaluable tool for industries like construction, farming, and geology.

Key Features That Set It Apart

One of the most notable features of gas-powered drills is their durability. Built to withstand tough conditions, they often feature rugged exteriors and powerful engines that are resistant to wear and tear. Many models are designed with ergonomic handles and vibration-dampening technology, making them easier to operate for extended periods. The ability to attach various drill bits also enhances their utility, allowing users to adapt the tool for different tasks.

Applications Across Industries

The applications of gas-powered drills are vast and varied. In construction, they are used to bore holes into concrete foundations or metal beams. Farmers use them to install fencing or drill into frozen ground, while geologists depend on them for sampling in remote locations. Even homeowners can benefit from a gas-powered drill when working on large-scale landscaping projects or home renovations.

Maintenance and Care for Longevity

Like any tool powered by a combustion engine, gas-powered drills require regular maintenance to ensure optimal performance. Key steps include cleaning the air filter, checking fuel lines for leaks, and ensuring the drill bit is sharp and correctly aligned. Proper storage is also essential, particularly in colder climates, where fuel can degrade over time. Investing time in care and maintenance will extend the life of the drill and ensure consistent performance.

The Environmental Factor

While gas-powered drills offer undeniable advantages, they also raise environmental concerns due to fuel consumption and emissions. Some manufacturers are working on eco-friendly models that reduce carbon footprints without compromising power. Users can contribute to sustainability by selecting high-quality fuel and adhering to best practices for efficient operation.

Conclusion: The Indispensable Tool

The gas-powered drill remains a vital tool in today’s toolbox, providing unmatched power, portability, and versatility. From professionals on construction sites to hobbyists tackling ambitious projects, its capabilities continue to impress. While considerations like maintenance and environmental impact are important, the benefits of owning this powerhouse far outweigh its limitations. With proper care, a gas-powered drill is more than just a tool—it’s an investment in precision and productivity.