PP woven bags, also known as polypropylene woven bags, have gained immense popularity across various industries due to their durability, flexibility, and eco-friendliness. These bags are manufactured using a weaving process that interlaces polypropylene strips, resulting in a robust material ideal for packaging and transporting a wide range of products. In this article, we will explore the features, benefits, and applications of PP woven bags, along with insights into leading PP woven bag manufacturers and their offerings.

The Manufacturing Process of PP Woven Bags

The production of Woven sack bags begins with the creation of polypropylene fibers. These fibers are woven together using advanced machinery to form a fabric that is both lightweight and strong. The weaving technique ensures that the bags can withstand significant weight and rough handling without tearing or breaking. Manufacturers can customize the specifications of these bags based on customer requirements, including dimensions, colors, and GSM (grams per square meter).

Key Features of PP Woven Bags

- Durability: PP woven bags are designed to be tear-resistant and can endure harsh environmental conditions.

- Water Resistance: Many woven sacks are treated to be water-resistant, making them suitable for storing moisture-sensitive products.

- Recyclability: These bags are recyclable, contributing to environmental sustainability.

- Customization: Manufacturers offer various options for customization, including printing, size variations, and additional features like liners for enhanced protection.

Applications of PP Woven Bags

PP woven bags find applications in numerous sectors due to their versatility:

- Agriculture: Used for packaging grains, seeds, fertilizers, and animal feed.

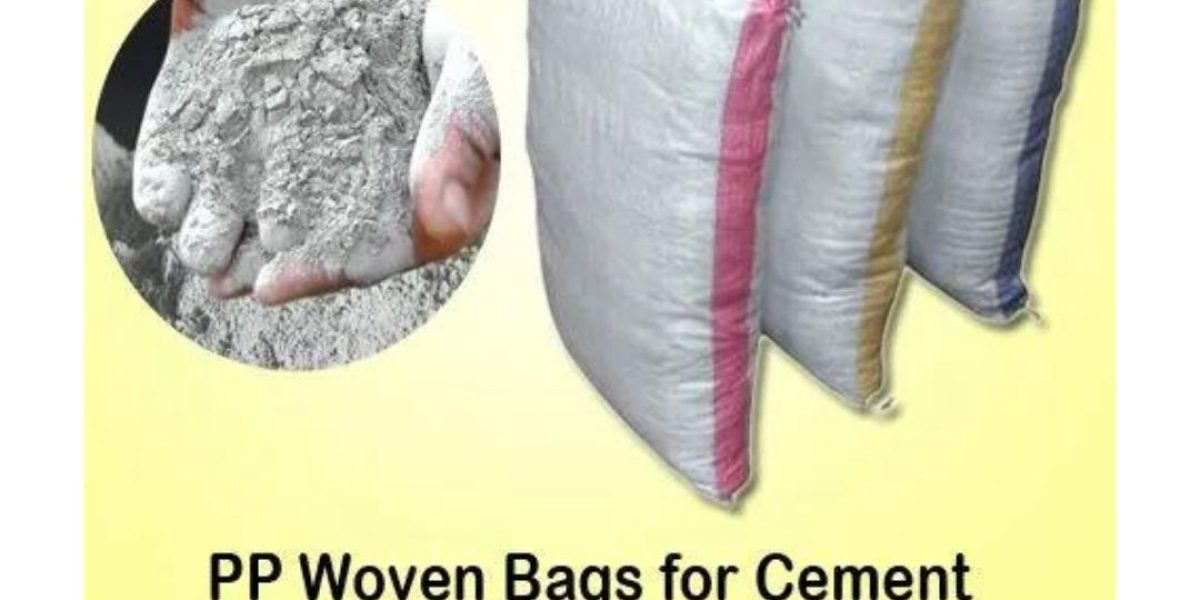

- Construction: Ideal for transporting cement, sand, and other bulk materials.

- Food Industry: Suitable for packaging food grains, sugar, flour, and spices.

- Chemical Industry: Employed for packaging chemicals and granulated materials.

These bags can be tailored to meet specific industry needs, ensuring that they provide maximum protection and efficiency.

Advantages of Using PP Woven Bags

The advantages of using PP woven bags over traditional packaging solutions include:

- Cost-Effectiveness: They offer a lower cost per unit compared to other materials while providing superior strength.

- Lightweight Design: Their lightweight nature reduces shipping costs and makes them easier to handle.

- Eco-Friendly Option: Being recyclable contributes to reducing plastic waste in the environment.

Leading PP Woven Bag Manufacturers

Several manufacturers specialize in producing high-quality PP woven bags. These companies focus on innovation and sustainability in their production processes:

- Sah Polymers Limited: A prominent manufacturer in India known for producing lightweight yet durable PP woven bags tailored to various industries’ needs. Their commitment to quality ensures that the bags maintain the integrity of the contents during transportation1.

- Anjani Interweave: This manufacturer offers a wide range of polypropylene woven bags designed according to customer specifications. They focus on flexibility and strength in their bag designs2.

- Chittor Polyfab: Known for its quality assurance processes, Chittor Polyfab manufactures reusable PP woven bags that cater to diverse industrial applications3.

These manufacturers not only provide standard products but also offer customized solutions based on specific requirements.

Innovations in PP Woven Bags

The industry is witnessing innovations in the design and functionality of PP woven bags. Some notable advancements include:

- BOPP Laminated Bags: These bags feature a layer of Biaxially Oriented Polypropylene (BOPP) film that enhances print quality and provides additional protection against moisture and UV rays6.

- Woven Sacks with Liners: These are designed for products requiring extra protection against leakage or contamination. The liners help maintain product integrity during storage and transportation5.

Conclusion

PP woven bags have emerged as an essential component in modern packaging solutions across various industries. Their durability, cost-effectiveness, and eco-friendliness make them an attractive alternative to traditional packaging materials. With ongoing innovations from leading manufacturers like Sah Polymers Limited, Anjani Interweave, and Chittor Polyfab, these bags continue to evolve to meet the dynamic needs of businesses worldwide. As industries increasingly prioritize sustainability alongside functionality, the demand for high-quality Woven sacks bags is likely to grow even further in the coming years.

Frequently Asked Questions (FAQs)

What are PP woven bags made from?

PP woven bags are primarily made from polypropylene fibers that are interwoven to create a durable fabric suitable for packaging various products.

How do I choose the right size of a woven sack bag?

Choosing the right size depends on the volume of the product you intend to package. Manufacturers typically provide guidance based on standard sizes or can customize sizes according to specific needs.

Are PP woven sacks environmentally friendly?

Yes, while they are not biodegradable, PP woven sacks are recyclable and can be reused multiple times, making them a more sustainable option compared to single-use plastic bags.